Reduce Scrapping and Smelting, Promote Component Reuse > Unpowered, Hand Tools

> Metalworking Tools

> Knife grinder plans no weld 2"X72" belt metal abrasive

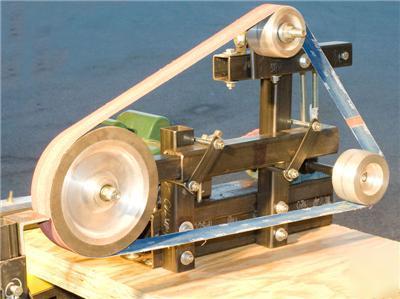

Knife grinder plans no weld 2"X72" belt metal abrasive

Knife Grinder Plans No Weld 2"x72" Belt Metal Abrasive

Set of Plans for 2"x72" Belt Grinder

* Simply google "No Weld Grinder"

* No Welding or Maching required.

These printed plans are for a 2 x 72 belt grinder or sander. The construction requires no welding, no machining, no lathe work, no precision thread tapping, no special tools.

These are paper plans and will be mailed to you via US First Class Mail upon purchase.

Just to be sure, this is not for an actual grinder or any part of grinder. This listing is for plans that you can use to construct your own grinder/sander using your materials.

This grinder design uses tool arms to change from a contact wheel to a flat platen to a small wheel to slack belt attachment in seconds. If you have a KMG grinder from Beaumont Metals already, you can use the tools from that grinder in your NWGS.

* No Machining or Mill work needed!

* 15 pages of clear CAD drawings with measurements and materials list on each drawing.

* Quick change tool arms allow multiple attachments to be changed in seconds.

* Plans include tool arms for: Flat Platen, Tool Table Rest, Slack Belt, Contact Wheel.

* Very low cost materials used in the construction.

* Rock solid and vibration free.

* Tool Table Rest design allows tool rest to be used with any attachment.

* Flexible design allows different belt lengths to be used besides 2 x 72 .

* No precision thread tapping required.

* Design is a no weld design but the grinder can easily be welded if you desire.

* Flexible, robust design allows you to make changes to customize your grinder/sander to your own needs. If you make tapered tangs on your knives or have wanted to, simply stretch the plans and make a 15 flat platen with ease.

* Can use KMG tool bar arms.

* Hundreds of hours of R&D and multiple proto-type testing went into the design of this very capable grinder/sander.

* Web support with additional pictures and ideas for other attachments via

* Suitable for use in grinding metal and sanding wood. In case you are wondering, when you are working with metal, the machine is called a grinder, when you are working with wood, the machine is called a sander.

* 2 x72 abrasive belts are one of the most common and competitively priced sizes of belts. Compare prices on this size belt to any other. If you are using a smaller size grinder/sander. The money you save using 2 x 72 belts will pay for this machine in no time flat.

* 2 x 72 belts have more types of belts available for them than any other size belt. It s no wonder that knife makers and custom wood workers have settled on this size of grinder/sander.

You can contact me directly at ****@usakms.com