Reduce Scrapping and Smelting, Promote Component Reuse > Engine Powered

> Turbine

> Cook County

> New

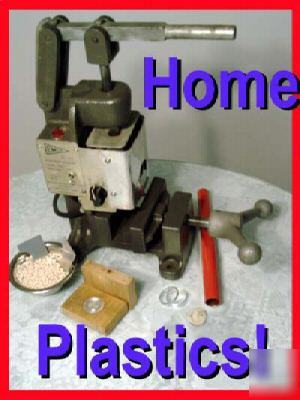

> Plastic injection molder emco ton press granulator mold

Plastic injection molder emco ton press granulator mold

Do you have an interest in learning:

3) How to Make Your Own Injection Molds Inexpensively

4) Repair the Equipment you Already Own or Plan to Own.

This CD-ROM disc contains everything you need to know to get started in the exciting field of Plastics Technology. Think of all of the great ideas you have regarding inventions and money-making items. If only there was a way to make them. Yes, there is a way. In fact, the machines have been in operation since the 1960s and became commonplace in the 1970s.

Used equipment regularly sells online for a fraction of their original price. The CD-ROM shows you how to use small tabletop equipment made by EMCO. This equipment is still used today in schools, laboratories, workshops, specialty shops, prototyping companies, and R&D research departments throughout the world.

The technology is applicable to the following equipment:

1. Emco and Powerlab Injection Molders 1/4 oz, 1/2 oz, 3/4 oz, 1 oz (works great.)

2. Emco and Powerlab Rotational Molder 812 and smaller models (works great.)

3. Gingery Do-It-Yourself Injection Molder (highly recommended book series)

4. Many more models (1960s-2008 models.)

The 8 videos contained on this CD-ROM are all original and take you step-by-step through the rebuild and repair of the Emco Injection Molder. The following problems are covered in detail:

1. Electrical Repair Including Rewiring

3. Rebuilding the Circuit Breaker, switch, Indicator Lamp

4. Disassembly, sandbast, repaint, reassemble

The Plastic Injection Molder Technology allows the home user to make products that rival the Big Boys. These tabletop machines produce amazing quality parts in low volume. That is the key isn't it- low volume. If you plan on making just a few parts, prototyping, or plan on selling a few items per day rather than by the truckload- the small molders will do the job just fine.

1. A small hobby lathe (Harbor Freight 7x10 mini lathe)

2. Of course the Emco molders mentioned above

3. A mid-sized mill/drill (Harbor Freight 12-Speed)

4. Hammer, wood, aluminum rod stock (big boy lathe cutoffs work great)

5. Common household items to recycle and granulate scrap plastic

If you work in the industrial arts, you probably have access to scrap aluminum turnings and bar stock cutoffs. If not, online vendors sell aluminum inexpensively. Don't worry- a little aluminum goes a long way. The traditional way to make a mold is with a heavy 10-20 ton plastic injection molder requiring 480V and 3-phase power. What a beast (I mean that in a good way)

The departure from the ENOROMOUS molders is that we want to make a few parts cheaply, inexpensively, and fast (under 5 minutes is fine for one part for the everyday user- don't you think?) The small molders used in the CD-ROM video segments run on standard household electricity and don't run up your electric bill.

In fact, once your mold is made, you can produce many molded parts from it. It is reuseable. The exact parts count is unknown. If you are careful, it can last many years. Well, how does it work? We use hardwood milled to size for the actual mold. The precision and durability is due to the use of Inserts made of aluminum. In reality, the part is completely surrunded by aluminum during the molding process. The wooden block is simply to hold all of the inserts together and provide a seal. You will be amazed at what you can make at home.

Ok, well we've talked about the injection molder technology quite a bit. What about the rotational molder? Emco made a rotational molder that is truly wonderful. Unfortunately, very little information is available about this machine. Through research, I was able to find alternate brands to the Emco such as Powerlab. The Powerlab is still being sold today as anew unit costing $1500 or more. It resembles the Emco and looks to me like it may be identical. The used Emco 812 rotational molder I purchased online had typical problems and needed some attention to the drive system. It wasn't a difficult fix. In fact, the fix required 5 minutes of time to perform. It required no purchase of replacement parts. Easy and simple fix. It solves the slack problem that develops after decades of use. No more sloppy mold turning. Smooth steady rotations are what you seek. Right.

This is a CD-ROM (CD-R) made by a true enthusiast of Plastics and machinery. I don't try to re-invent the wheel and use of existing technology is the key. The innovations are evolutionary rather than revolutionary. The use of commonly available parts through McMaster Carr, Radio Shack, Home Depot, Ace Hardware, and more are great sources of parts. You will learn how to fix your machines and have great results. You will also learn about how to make your own injection mold and form your own parts.

The videos are made from a professional quality video camera and play on any PC. Instructions are included on the CD-ROM for the installation. No it is not a DVD. It is a CD. This CD uses AVI files with the DIVX codec. New style DVD players can play DIVX movies (look for the word DIVX on the front of your new DVD player. No, a new DVD player is not required. If you have one- just pop it in and watch. If you have a PC (most people have access to one at home or work) you can install the CD and watch the videos through Windows Media Player.

The videos have full sound and realtime playback that rivals DVD quality. I wanted you to be able to see and hear every sound the machines and process makes. There is no narrator. Let me say it again. The videos are not narrated. You will need to read in addition to viewing the videos.

There is a step-by-step article about all of the videos. In addition, there is a summary of plastic types (Acrylic, PVC, UHMW, LDPE, HDPE, and more) and key information abouty those plastics. In addition pics of wiring diagrams, illustrations, dimensions, and more are included to help you build your own duplicate injection mold.

This is intended for beginners to intermediate users. If you have a large machine and produce thousands of parts daily and don't have a problem spending a thousand bucks just on an aluminum block to make a mold- then this CD isn't for you. My target audience is the person looking for a way to get started in plastics. Make some cool parts and gain some do-it-yourself experience. If you have zero patience or have constant distractions- this isn't for you.

CD was as described- very fast. Thank you

The work shown requires patience and skill:

1. To install the CD-ROM to get it to play (if you are not PC literate have a friend help -

or EMAIL ME. with as many questions as it takes for you to understand.

3. Must be mechanically inclined

Think Green. Make Money and Recycle at the same time.