Reduce Scrapping and Smelting, Promote Component Reuse > Engine Powered

> Diesel

> Cook County

> New

> Seho 8240 mws 8200 wave soldering machine system

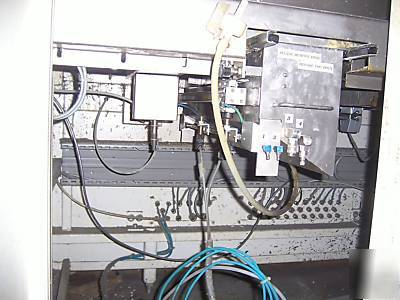

Seho 8240 mws 8200 wave soldering machine system

This listing is for a wave soldering system / machine / station.

* Series: MWS-8200 (MWS8200)

* Model #: MWS-8240 (MWS8240)

* Voltage: 3 x 208V / 60Hz / 4W

* Overall Dimensions: Approximately 10' (wide) x 5' (deep) x 72" (high)

Here is some information from the manufacturer. Please note that this is general info on the MWS 8200 series. This listing includes the machine described above and pictured below. Please call or email if you have any questions regarding this system.

Soldering System MWS 8200 Modular Wave Soldering System for Medium- and Large Production Environments

* Modular additions possible, grows with yourrequirements

* Flexible because of a multitude of possibleconfigurations

* - A choice of fluxers

* - A choice of pre-heaters (Length, Type of HeatTransfer: IR/Convection)

* - A choice of control concepts

* Convection pre-heater for homogeneous andgentle heating

* Highest soldering quality due to SEHO's double-wave system

* Economical soldering because of high-performance functional elements

* Optional: nitrogen hood ALIX LT for a localizedinert atmosphere

* Excellent accessibility due to an ergonomical design

* Visual access into process area offers direct information

* Modularity of control system allows updating

* User friendly with graphic visualization

* VDM: Visual Representation of EquipmentFunctions

* High process reliability due to feed-back loops

* SPC Statistical Process Control

The Wave Soldering System 8200 has been developedto meet the requirements of large and medium sized production. As its major advantage must be seen the ability to grow with your requirements.

SEHO has incorporated a full range of options to allow for greatest flexibility. Should your requirements change in the future, the Power-Line MWS 8200 PWR can be upgraded without difficulties.

For example, if you find that the pre heating zone is too short for new products (Standard: 1800 mm) SEHO can add additional pre-heat modules.

Even the control system is laid out to accommodate future additions without any problems. The fluxer of these models is not integrated into the main frame but housed in anextra module. This idea permits the user to lengthen thes ystem at a future date.

Robust design was stressed. Robustness and ease of access yield a high degree of up-time. Latest findings andtrends in ergonomie design have been incorporated by SEHO in order to allow visual control of all process steps.

The Fluxer:Designed for thnewest fluxes

The MWS 8200 may be equipped with different fluxers, depending on the flux to be used.

Derived from the proven FDS reflow-line, it is equipped with tangential blowers which produce an absolutely ho-mogeneous temperature environment over the full width of the conveyor and for the entire length of 900 mm. All of the heating modules are designed to be low in maintenance and of easy access.

Highest soldering quality SEHO's soldering unit consists of a double wave system which assures best soldering results even for complex SMD assemblies. The Chip-Wave promotes wetting in critical areas of the assembly because of its high kinetic energy. The Delta-Wave offers long immersion times andexcellent surface definition and thus forms optimal solderjoints. Both solder nozzles may be removed quickly andeasily in case of maintenance. Backing out of the solder module from the machine is greatly facilitated by an inte-grated rail system. The pumps are driven by electronically controlled motors. As an option, SEHO offers the nitrogenhood ALIX LT. Localized nerton of the solder unit greatly reduces the dross production and eliminates environmental hazards such as dust and fumes. The reduction in oxideformation further improves the soldering quality.

All aspects of the system are graphically represented on the screen and this visualization further simplifies the manipulation and control of the process. It is VDM, a program which graphically depicts the equipment functions, which permits direct access to all real-time variables as well asset-points. Even maintenance items for the most important parts of the MWS are incorporated. On-line help for main-tenance questions provides quick information in case of error messages.The software is compatible with all available versions ofWindows .

:For your specific application SEHO's finger conveyor is made of non-corroding material. Assemblies are held reliably and transported smoothly through the soldering process. A number of different types of fingers is available depending on the specific propertiesof the assembly. SEHO's proven belt conveyor features low maintenance. Appropriate pallets can hold even oddly shaped PCBs and assure well defined and warp-free performance within the entire system.

* AZ to NV/UT/NM/CO - $700