Reduce Scrapping and Smelting, Promote Component Reuse > Electric Powered

> Woodworking

> DuPage County

> Used

> Physitemp nte 2A thermal sensitivity ptu 110A pumptank

Physitemp nte 2A thermal sensitivity ptu 110A pumptank

Physitemp NTE 2A Thermal Sensitivity PTU 110A Pump and Tank unit

* Model: NTE-2A Thermal Sensitivity Tester

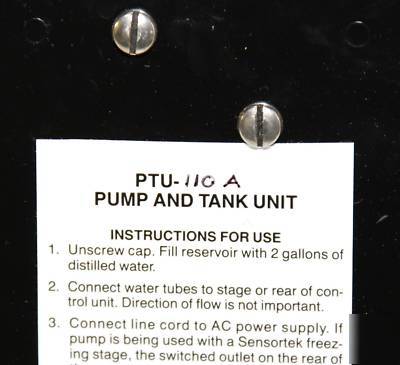

* Model: PTU-110A Pump and Tank unit

Controller Specifications NTE 2A

20-30 C (Preset adjustment) and 20.5 either side of nominal set point in switchable 0.1 steps.

Continuously adjustable with flat bladed screwdriver

Thermal Probe Specifications NTE 2A

6.5" long probe. Total length with cable, 6 feet

Temperature Controlled Surface Area:

Note: Sustained exposure to temperatures over 46 C can cause burns. This equipment is not intended for use at temperatures over 45 C

Less than 4 seconds in heating of cooling

The NTE2A Thermal Probe is a sophisticated, non-invasive device for the clinical evaluation of neuropathy and the assessment of short fiber neurological function. Individual thresholds are compared to normals that can then be used to track nerve function over time. It can also be used for pain studies and in any application where a variable, accurately controlled temperature stimulus is required.

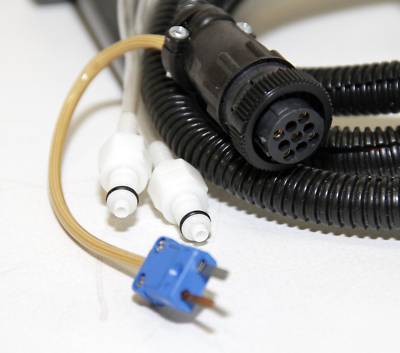

The equipment comprises a hand held pen-shaped probe with a smooth flat tip 13mm in diameter on a 5 foot lead, a digitally set temperature control unit and a recirculating pump with a combined water reservoir, which is required to cool the probe during operation.

The thermal probe, or thermode, utilizes a Peltier semiconductor heat pump to provide temperature stimuli above and below room temperature. The temperature range of the thermode extends from 0 to 50 degrees Centigrade and the response time to a step change in temperature is extremely fast , less than 4 seconds in the heating or cooling mode.

Pump and Tank Unit was designed for use with Physitemp's range of thermoelectric cooling and heating stages. It provides a convenient reservoir of cooling water when a stage is operated in the cooling mode for an extended period of time in a location which has no source of tap water nearby to cool the hot side of the thermoelectric heat pump. The reservoir tank holds seven gallons of water, which is adequate to run the smaller stages like the TS-4 series Thermal Stage or the BFS series 3 or 5 Freezing Stages for up to eight hours and a larger stage like the BFS-30 for up to four hours.

Water is circulated using a quiet 1/25 horsepower single phase motor and magnetically driven pump - so there are no rotating seals to leak or replace. Self sealing connectors are used on the inlet and outlet water connections to prevent spillage. Ice cubes may be added to the tank in order to extend the operating time or reduce the lowest temperature to which the thermoelectric stage can cool. A switched accessory outlet on the read of all thermoelectric controllers and power supplies is used to power the pump so water starts flowing immediately when the controller is turned on.