Reduce Scrapping and Smelting, Promote Component Reuse > Electric Powered

> Metalworking

> Lathes

> New

> Alar wastewater treatment system model 220 sludge

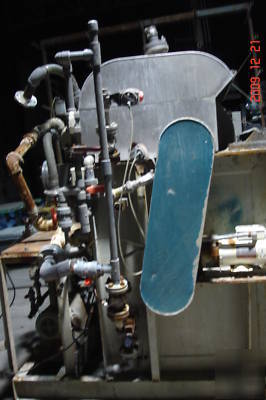

Alar wastewater treatment system model 220 sludge

ALAR Auto-Vac Wastewater Treatment System

See the website: http:// /equipment/auto_vac.html

Nominal Filtering Area: 12.6 sq ft

Overall Filter Skid Size: 6'2" x 9'0"

Auto-Vac WasteWater Treatment Equipment

* Filters down to micron (.0005mm)

* Reduces volume of dry solids by 95% for easy disposal

* Available in both manual and automatic configurations

* Self-contained for easy installation

* Dewaters sludges generated by:

* Porcelain & Enamel Fabrication

* Metal Plating & Finishing

* Pharmaceutical Manufacturing

* Numerous other applications

Auto-Vac WasteWater Treatment Equipment is ideal for cleaning up waste streams from:

* Chemical Precipitation Systems

The Alar Auto-Vac filter is self-contained wastewater treatment equipment used for a variety of water-based sludges. It economically separates sludge into solid waste and water clean enough to be disposed in sewers or re-used within your plant.

Water pollution control is one of this country's top priorities. The E.P.A., fueled by growing public pressure, is tightening the regulations on what may and may not be discharged into our sewers or disposed of in landfills. Liquid waste disposal is virtually non-existent and is completely banned in 98% of the U.S. today. The government has placed the responsibility of those companies using water in their processes to meet these strict E.P.A. guidelines. These efforts preserve our rivers and streams and ensure safe drinking water far into the future.

To comply with these regulations industries are faced with exorbitant hauling costs, expensive off-site treatment, increased municipal user fees and the burden of cleaning up wastewater lagoons. Non-compliance results in heavy fines and may even lead to complete plant shut down.

The most sensible and cost-effective solution is to clean up wash water at the source through Sludge Dewatering Equipment. Alar Engineering Corporation has been designing and manufacturing Sludge Dewatering Equipment since 1970. Utilizing the latest in technology and advanced research methods, Alar provides industries of all types with state-of-the-art, time proven equipment.

With over 1,500 installations worldwide, Alar Engineering is the dominant force in responsible wastewater management.

To achieve the individual discharge requirements of industries worldwide, Alar custom designs and manufactures the most advanced Sludge Dewatering Equipment.

Alar's knowledgeable, in-house engineering department and sales consultants provide you with expert technical support and continued service.

One of the most common needs in today's manufacturing environment is Sludge Dewatering Equipment and meeting discharge limits. Alar's Auto-Vac system effectively removes solid particles from the sludge, producing dewatered dry waste. Typically, this waste is disposed of at a local landfill without further drying.

The Alar Auto-Vac Sludge Dewatering Equipment is skid mounted, pre-piped and pre-wired for easy installation. It is offered both with semi-automatic and automatic modes of operation. This design works with virtually any industrial waste such as coolants, cleaners, and process waters.

The operation of this Alar Auto-Vac Sludge Dewatering Equipment is semi- automatic. The operator charges the pre-coat tank with filtering media called diatomaceous earth, or D.E. The D.E. slurry overflows into the filter pan, and the vacuum draws the D.E. filter media onto the cloth, building up a 3" cake. The water passes through the D.E. media and out a hollow shaft. This pre-coat operation takes about 15 minutes, and is performed with each shift. This D.E. media is capable of removing particles as minute as of a micron. That's of 1/1000th of a millimeter.

Filtering is performed in much the same manner as pre-coating. The wastewater is pumped into the pan. The level controllers, located within the pan, maintain a constant liquid level; eliminating the need for operator attention. The vacuum draws the liquid through the D.E. media and out the shaft. The solids are trapped on the surface of the diatomaceous earth where they are air dried for 2/3rds revolution of the filter drum. This process removes virtually all of the free moisture by drawing an amazing vacuum of 26 inches of mercury.

These solids are continuously removed from the surface of the cake by an extremely durable stellite knife blade advancing with lathe like precision leaving a clean surface as the drum re-enters the sludge.

The Auto-Vac is self-cleaning with every revolution which prevents blinding or clogging, and provides rapid filtration and extremely high filtrate clarity.

After a long day of continuous use, the D.E. will be exhausted and the Auto-Vac is now ready for quick and easy cleanup. Cleanup is performed by activating the water nozzles on the Auto-Vac's spray bar. The cleanup water is minimal and is filtered with the next batch. With an automatic option, the Auto-Vac can repeat the pre-coat process and go back on line, or shut itself down. From start to finish, the Auto-Vac is designed for ease of operation with minimal manpower required, providing remarkable results.

The Alar Auto-Vac substantially reduces operation and disposal costs by typically achieving reduction in volume of 90 to 95 percent and producing landfill-ready solids.

The facts are clear, no longer will the E.P.A. allow misuse of our landfills, and water treatment regulations will only get tougher. Waste hauling is expensive in comparison to an Alar filtration system. The Auto-Vac filter is the economic solution to compliance issues and disposal costs.

Alar's technical sales staff and field engineers are available to help integrate the Auto-Vac into your facility and maintain on-going support.

In today's environmentally conscience world, sludge dewatering can no longer be avoided, it's a part of plant operations. Alar offers a sensible, effective solution to your wastewater problems.

The Auto-Vac filter separates sludges into solids and water which can be typically disposed in sewers and recycled. Pre-piped, pre-wired and skid-mounted, the Auto-Vac is easily added to any manufacturing processing facility.

As water is vacuumed through a filter aid media, solids accumulate on the filter drum's surface. A variable speed knife advanced, removing the solids from the drum's surface with lathe-like precision. The solids simply fall off and into a standard dumpster.

The operator starts the filter aid mixer and adds the filter aid. When it is mixed, he then opens the water valve. This will overflow the filter aid slurry into the filter pan. Next he starts the vacuum pump. The vacuum pulls the filter aid onto the cloth-covered drum, building up a layer of filter aid approximately 3" thick. The pre-coat water passes through the filter aid cake, out of the hollow shaft and through the vacuum pump.

The liquid that is to be filtered is fed into the pan (feed tank by others). Level controls maintain a constant liquid level in the filter pan. The liquid is pulled through the filter aid cake by the vacuum, out of the hollow shaft and through the vacuum pump. The solids are left on the surface of the filter aid cake. These are continuously removed from the surface by a knife blade advancing with lathe like precision leaving a clean surface for rapid filtration. Semi-dry solids are collected in a container for disposal.

When the knife is approximately " from the drum surface, it will automatically stop. The operator then lets the pan empty to the bottom of the drum, opens the filter pan drain valve, stops the vacuum pump, opens the spray header valve and washes the filter. This wash water should be fed back to the feed tank so it can be filtered with the next batch.

Alar Auto-Vac and Belt Press Equipment Comparison

Polymers Optional. Little or No Polymers Needed.

Polymers: Not an Option. Polymers Needed.

Uses Diatomaceous Earth. Filters to Micron Size.

No Diatomaceous Earth. Filter Media > 15 Microns

Forgiving of Polymer Overdoses

Polymer Overdose will Require the Batch to be Repeated.

Fully Automatic Systems Require Less than 1 Hour per Shift of Labor.

A Belt Press Requires Precise Polymer Dosages, which Could Take Hours to Perfect Each Run.

Self-Cleaning with Every Revolution

Filter Cloth Requires Changing Every 3 6 Months, and Never Comes into Contact with Contaminated Waste.

Belt Media in Constant Contact with Contaminated Waste, which Causes Clogging and Requires Cleaning.

Scheduled Lubrication and Maintenance Once a Month.

Belt Requires Constant Checking of Tension.