Reduce Scrapping and Smelting, Promote Component Reuse > Complete Machines

> 1920 1940

> Cook County

> New

> Conversion kit-chesterton 4 M50 in-line viscometer +w&h

Conversion kit-chesterton 4 M50 in-line viscometer +w&h

Norcross in-line viscometer M50 Chesterton conversion kit

Updates M50 viscometer, which in the older years was supplied with 3-ring or 5-ring teflon packings.

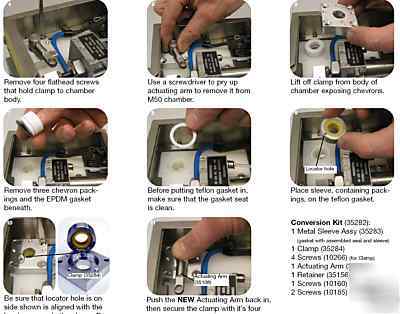

Kit includes all parts, hardware and instruction page nessesary to perform conversion and replace work actuation mechanism.

Comparable with M50 models manufactured prior to 2004 OR models supplied on Windm ller & H lscher flexo presses prior to 2006.

Reduce costly maintenance downlime and eliminate chance of ink leaks(see picture for an example of horrible out of control mess).

Chesterton seal is known to last at least 3-5 years on the M50 viscometer.

Teflon packings are often replaced twice a year.

I think that benefits are clear to any printing or maintenece manager!

M50 Viscometer - (please see supplied picture) is a true in-line viscometer based on

Norcross Falling Piston principle. Sensitive and robust, at the same time it's not affected by flow or turbulance. Last year it has been phased out by stainless steel viscometer M51. I am also able to supply other wearable parts for this device and will be listing some of them soon. If you require any additional information or technical support please contact manufacturer directly.

This is what M50 looks like with a cover removed:

This is what M50 looks like when it leaked and dried up beyond repair: