Reduce Scrapping and Smelting, Promote Component Reuse > Engine Powered

> Diesel

> DuPage County

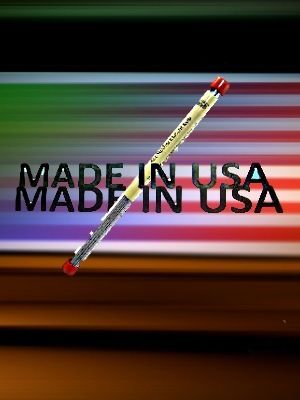

> #1 welding rod aluminum usa repair rods see video

#1 welding rod aluminum usa repair rods see video

1 PACK OF FLUXLESS ALUMINUM REPAIR ROD.

To watch video, click one time on youtube arrow.

CLICK HERE TO PURCHASE LARGE QTY AT WHOLESALE PRICE.

The below pictured skeg was rebuilt using my

Image Hosted by ImageShack.us Image Hosted by ImageShack.us

The above pictured boat was repaired out in the woods.

A cool breeze of about 5 miles per hour was blowing.

The compressor pictured below as leaking so much that it

was useless. I repaired it with my Special Alloy Rod and have

been using it for about 3 years with no leaks.

____________________________________________________________________________________________________________

The below came from a satisfied user.

___________________________________________________________________________________________________________________

The below email was received from a gentleman in Canada.

********************************************************************************************************************

Just a short note to praise your aluminum welding rods. We own and operate

a fishing resort in Ontario Canada. From our resort we have boats on 12

lakes. When the season ends we turn the boats over and take the out boards

back to our main lodge. After many years of chatting at the Dallas Boat

Show you sold me a tube of your product. In June of that year we had a

flood. My boat on one of our portage lakes broke loose and when I found it,

it was rubbing on a rock. End result was a hole about 1 inch long and 1/8

inch wide. My solution was me and 2 other fellas to drag a 16 fot Lund 1

mile through the woods, tow the boat 25 miles to town and pay to get it

reapired. The alternative was to walk the 1 mile into Ash Lake with a few

of your rods and a propane torch. Voilla!! All is well. This testimonial

can be verified at 1-(***)-274-4046 or at the Dallas Winter Boat Show in booth

311. Thanks Big Guy. You saved me a lot of work and $$$$. Those rods will

Glen Treflin, Northern Lite Camp, Fort Frances, Ontario, Canada. Fishing at

PS: I also have a sucess story of fixing an aluminum boat that was turned

over for the winter and had a hole punched through it by a snow machine ski.

*****************************************************************************************************************

The torch you see me using in above picture works very well. This is a 5000 bernzomatic. Purchase in any hardware store.

You will receive full, easy to understand instruction with the pack of rod.

Satisfaction is guaranteed or your or your purchase price will be cordially refunded upon return of the unused portion of the merchandise.

S&H, please use rate calculator.

In the early fifties, I started fooling around with trying to weld aluminum with a torch. I had no idea how hard it was, til I tried.

I burned up a lot of aluminum.

I finally learned how to repair aluminum with a torch, with great difficulty and I sometimes burned my aluminum up even when I thought I knew what I was doing.

No more burning up your aluminum.

We have developed a rod that makes it so easy to repair aluminum with any kind of torch, that even an amateur can look good even on the very first try.

This newly developed rod repairs cast aluminum, die cast, extruded, sheet aluminum, pot metal. Aluminum from Japan, Russia, England, France, Fiji Islands, United States or where ever.

This rod repairs aluminum that was made yesterday, or aluminum that was made in the year l888. It is non-discriminatory.

It is compatible with all aluminum alloy.

This new rod will repair any metal that a magnet will not attract.

It is actually true, you can be a success on the very first try.

A propane torch puts out 2600 degrees farenheit. Aluminum melts at 1200 degrees farenheit.

A propane torch puts out over twice the heat needed to melt aluminum.

Just clean your aluminum down to bare metal. Use a file, grinder, sand paper, sandblast or brush it off. Just do not use any chemicals.

Heat the aluminum. Use your rod for a test stick. When your rod starts to melt, you know you have the aluminum workpiece hot enough to repair.

I will guarantee you that you will not burn your aluminum. You will be a success on your very first try.

I have 100's of written testimonials as to the success inexperienced people have had with this aluminum repair rod.

T.D.B. says "Repaired boat prop easily in minutes."

I do business with many boat dealers and one of the boat dealers employee said he repaired a junk boat with my Special Alloy Rod and here is what he said - " I had a Monark. Filled it up with water and found 32 holes. I use the rods to weld up my holes and now I have not 1 leak."

Bert S. says "Patched a crack in lawn mower crank case - It works!"

Steve B. says "I have used this rod to repair racing heads on dirt track cars and this is absolutely amazing how easy & well it works."

One gentlemen says "Repaired barrel sleeve on Beretta 22 target pistol with aluminum repair rod."

Aluminum Repair Rod will even repair "pot metal."

Many welders will tell you that it is impossible to repair pot metal.

The jeep door hinge you see in the below picture is pot metal.

The wind blew the door open and the hinge broke completely off.

I welded it with ease with my Special Alloy Rod and it is one piece of metal now. The hinge is now stronger than it was when it came from the factory.

was Image Hosted by ImageShack.us

The electrical conduit fittings you see below are some of the sorriest pot metal ever made. I took two new ones, cut the ends off and welded them together. They are one piece of metal now. Image Hosted by ImageShack.us

I repaired a compressor head with this rod.

The threads were stripped out.

The compressor was completely useless and a new head was not available.

The compressor does not leak and it has been going for over 2 years after the repair. Picture of compressor below.

The top of the tripod that I welded on is pot metal and it is stronger now than when new.

The skeg on the boat motor was repaired with a propane torch and my SPECIAL ALLOY ROD.

The head shown below was repaired with a propane torch and my SPECIAL ALLOY ROD.

I repaired the jon boat pictured with my Special Alloy Rod. Took about 5 minutes. Image Hosted by ImageShack.us

Mr. W.H. says "I repaired 1976 Harley motorcycle. Outside case cover had a crack and hole. Filled the crack and hole, then polished. Works perfectly."

Mr. K.F. says "I used aluminum repair rod to repair leaking rivets on an old jon boat and it worked well."

Mr. CAP in Corpus Christi, Tx says "I repaired broken tip of outboard aluminum propeller with aluminum rod and was as hard as original.

You can repair boats, jon boat, canoes, lawnmowers, motorcycles, air conditioning equipment, refrigeration units, drill motors, routers, saws, blocks, heads, oil pans, valve covers, chainsaws, weedeaters, four wheelers, all kinds of air tools and the list goes on and on.

I sell aluminum repair rod to welders, auto mechanics, motorcycle mechanics, boat repairmen, outboard motor repairmen, radiator repairmen air conditioning repairmen and lawnmower mechanics all year long many times for $49.95 for a pack of 25 rod. About $2 per rod.

aluminum repair rod. Approximately 1 pound.

Each rod is 18" X 1/8". We do not cut our rod into short 9" lengths.

Just file, sand, grind, or sandblast down to bare metal and you are ready to start. No need to have to use a stainless steel brush.