Reduce Scrapping and Smelting, Promote Component Reuse > Electric Powered

> Food Processing

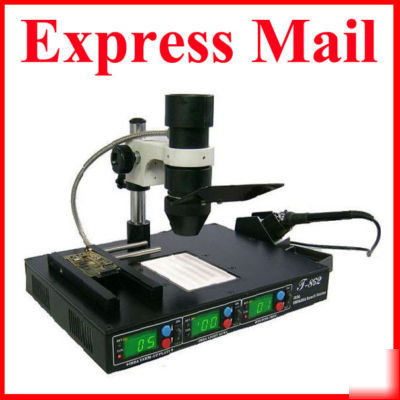

> T862 irda infrared bga smd soldering rework station 2

T862 irda infrared bga smd soldering rework station 2

Brand new T862 IRDA Rework Station

able to solder/desolder IC size : 15x15-20x20mm .

4. No need weld tools,it can weld all the component of 15x15-20x20mm.

6. Infrared heating no have sirocco flow. Don't impact perimeter small component.Can suitable for all of the component,especially Micro BGA component.

Check the power source,wind the plug.

Turn on the power source.Don t use until pass check.Pand will display enactment value.When last time used.

Installation the repair shell.Fix the line on the strip rack.Screw the light system height.Keep 20-30mm between light and welder machine.

According to measurement of welder piece.Proprictily screw temperature.from60 -350 .When you strip 15 15mm piece.Choice temperature 240-300 .When you strip 25 25mm piece.Choice temperature 300-350 .The temperature come up to 350 .The light system will shoot straightly.Please pay more attention to yourself control time.avoid burn out.

Screw focus.The light system smallest diameter is 15mm .the biggest is 30mm.Normally keep 20-30mm.

Turn on the two switches.They control warm-up plate and light system.

Regulate temperature , make the chip focus

After suitable for timing, the tin is clicked and melted, take out the chip.

Coating help solder flux (should not thick too , can have first more thin ) and soldering tin ball

Wait to help the solder flux to volatilize into the flux, heat and totally melt to the tin ball , place correctly with the clip , aim at the chip to weld into the position.

936 searing-iron.Open the swich and enactment temperature.