Reduce Scrapping and Smelting, Promote Component Reuse > Complete Machines

> Pre 1900

> DuPage County

> Smt to dip adaptors tssop-8 to dip-8 converter smd, #16

Smt to dip adaptors tssop-8 to dip-8 converter smd, #16

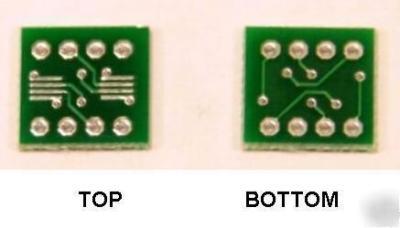

SMT -to- 0.100" DIP Adapter PCB

MSOP-8 / TSOP-8 / SSOP-8 / PSOP-8

to DIP-8 direct-to-socket converter

Breadboard and experiment with SMT parts

Row spacing: 0.300", ready for socket insertion

This listing is for style #16, shown below

For case: TSOP, TSSOP, MSOP, SSOP, PSOP

Pins accepted: standard or machined

Takes standard 0.100 header pins for legs. Can use standard square pins, or machined pins. Header pins not included, but available separately.

Extra long smt fingers, for easy iron-soldering without touching the IC leads.

High quality FR4 double-sided, plated-thru and tinned holes, with conformal coating solder mask.

Thermal lands provided to accomodate IC's with exposed metal thermal pads. These lands are "stitched" to the opposite side of the PCB with thermal vias to conduct heat away from the chip. These surfaces can also be used as ground planes in chips that don't have an exposed thermal pad.

Example of a finished adaptor, using machined header pins (pins not included)

Graphic pattern of available converters below (enlarged):

Catalog of other available patterns

Below: the right way to solder pins to a carrier.

You insert the pins in a solderless breadboard to keep them firm and parallel. Then seat the carrier PCB on top of them and solder. This way, you can even get away with combining smaller header fragments ( a 3 pin and a 4 pin to make 7 inline), and recycle what you already have.

Machined pins are ideal for breadboard use. They are as thin as most component leads, and will not stretch solderless contacts. Below: Machined Header pins. This is what you need- double male pins. These are gold plated. Search our listings for "machined"

This is a TOP solderd carrier. Pins are thru-hole soldered on the same side of the PCB which carries the IC

Limited support for IC's with thermal pads. IC must be precisely positioned on thermal land.

For greater thermal dissipation consider styles #14 and #17

Above: female machined sockets can also be used, if available, by inserting short lengths of thin wire in them. Use sufficient solder to fill the cup of the machine socket.

Why extra long SMT fingers for the IC?

Industrial PCB assemblers use machines, not humans to place parts on a PCB. The solder paste is applied by silkscreening (printed like an ink) and melted by reflow systems. These systems only require IC solder pads as small as a tiny dot, and they can get the IC soldered in position every time with pinpoint accuracy.

Humans don't work that way. If you use a soldering iron to accomplish this task, you need:

1. Space where to put the soldering iron tip when heating the pad, while maintaining a distance of 1-2 mm from the IC lead. (You should not touch the IC lead with the iron tip directly.)

2. Space to SEE what you are doing, so you can work accurately.

Don't get stuck with cheap Chinese imitations which give you no room to work.